Printing Processes In Packaging Design

From Concept To Creation: Understanding Key Techniques And Their Impact

![]()

Explore the art and science behind packaging design as we dive into the printing processes that bring brands to life. Each method offers unique advantages, shaping designs that capture attention and elevate brand presence. Discover how every technique—whether flexography, digital offset, screen printing, and many others—shapes visual appeal, reinforces brand storytelling, and enhances consumer experience.

Flexography is a high-speed, direct printing technique that utilizes flexible plates, making it a modern evolution of letterpress printing, tailored for rotary presses in fast-paced production environments. Widely embraced by the packaging industry, flexography offers remarkable versatility, capable of printing on an extensive array of substrates, including plastics, metallic films, paper, and cardboard. This flexibility allows it to meet the diverse needs of packaging, from food and beverages to personal care and beyond. Flexo printing applications differ between narrow web and wide web printing, primarily based on the size of the material. Wide web printing is better suited for larger substrates, while narrow web printing excels with smaller substrates, offering greater versatility, especially in inline finishing processes.

Key Advantages Of Flexography:

- Substrate Flexibility: Whether it's plastic films, foil, paper, or other materials, flexography adapts seamlessly, allowing for high-quality printing across a wide range of surfaces.

- Continuous Image Reproduction: Ideal for printing continuous patterns and designs, making it perfect for packaging that requires repetition, such as branded wraps or labels.

- Speed and Efficiency: Known for its fast drying inks and high-speed production, this process dramatically reduces turnaround times, ensuring quick, efficient, and high-volume production.

- Cost-Effectiveness: Flexography’s ability to handle large print runs with minimal waste and fast setup times makes it an economical choice for businesses, especially in sectors requiring bulk production.

- Food Industry’s Go-To: Given its reliability, hygiene standards, and ability to print on various packaging materials, flexography is the preferred method in the food and beverage industry, ensuring safe, high-quality packaging that meets regulatory standards.

- Advanced Quality: Recent technological advancements have significantly improved the precision and sharpness of flexographic printing, allowing for rich, high-definition images, complex patterns, and eye-catching designs that elevate packaging aesthetics.

As the technology continues to evolve, flexography has become synonymous with speed, quality, and versatility, making it a cornerstone in the world of modern packaging design. It allows brands to achieve vivid, consistent results across different packaging formats while keeping production efficient and cost-effective.

Digital printing represents a significant evolution from traditional flexography, offering key advantages, particularly by eliminating the need for physical plates. This shift brings immediate benefits in terms of setup-cost reduction and faster preparation times. In contrast, conventional flexography requires a unique plate for each design, driving up both time and cost for setup and production of printing cliches.

A cliché in printing refers to a printing plate or mold used to transfer an image or text onto a surface, typically through processes like flexography, letterpress, or offset printing. The cliché contains the raised or etched design, which is inked and pressed onto the substrate (such as paper, plastic, or others) to reproduce the image or text. In flexography, these plates are usually made of rubber or photopolymer, and each design requires a unique cliché, which increases costs and setup time for different designs.

Without the need for printing plates or complex assembly processes, digital printing is ideal for short runs, personalized packaging, and fast turnarounds. Final artwork is simply sent directly to the printer in digital format, allowing for quick changes between designs with minimal effort. This flexibility makes digital printing an attractive solution for brands looking for efficient, cost-effective packaging solutions that can be easily adapted to meet their needs.

In terms of print quality, digital printing offers exceptional sharpness, detail accuracy, and vibrant colors. Advanced machines like the HP Indigo deliver results that rival traditional flexographic printing, with high-definition quality and rich color saturation. This makes digital printing particularly well-suited for projects requiring premium quality and visual appeal.

At Imaginity, we have successfully executed short print runs with various suppliers, delivering top-tier packaging that meets the high standards of our clients. By leveraging the advantages of digital technology, we consistently achieve outstanding print results.

Pressure-Sensitive Labels (PSL) are renowned for their exceptional quality, which plays a pivotal role in enhancing product presentation and brand identity. The high standards of PSL production ensure that these labels not only look visually appealing but also perform reliably throughout their lifecycle. The integration of advanced printing techniques, such as flexography, screen printing, and stamping, allows for the creation of intricate designs, vibrant colors, and textures that capture consumer attention and convey brand messaging effectively. This focus on quality makes PSL an ideal choice for premium products, where presentation is key to influencing purchasing decisions.

Printing Pressure-Sensitive Labels (PSL) for packaging using narrow web technology offers the advantage of integrating flexography with additional techniques such as screen printing and stamping within the same manufacturing process. This combination enables the production of high-quality results, particularly beneficial for premium categories like cosmetics and beverages.

Pressure-Sensitive Labels (PSL), or self-adhesive labels on rolls, have emerged as a compelling solution for brands, offering a range of benefits, including:

- Enhanced Looks: The combination of flexography, stamping, and screen printing creates visually striking labels that attract consumer attention. This aesthetic appeal is crucial in crowded retail environments, helping products stand out on the shelves.

- Combination of Techniques: By merging flexography with stamping and screen printing, brands can achieve outstanding visual effects and textures. This multifaceted approach allows for intricate designs and vibrant colors that elevate the overall appearance of the packaging.

- Time and Cost Reduction: Streamlined processes lead to faster production and lower expenses.

- Versatility and Adaptability: The ability to customize designs for various campaigns and product lines.

- Ease of Use and Application: Simplified application methods make labeling efficient for manufacturers and retailers.

- Sustainability: The option to select eco-friendly materials aligns with growing consumer demand for sustainable practices.

- Enhanced Durability and Resistance: The use of robust materials and adhesives ensures labels can provide water resistance and immersion resistance without deteriorating. This durability is essential for products that may be exposed to moisture or varying environmental conditions, ensuring the labels maintain their integrity and visual appeal throughout the product's lifecycle.

Screen printing is a highly versatile and widely utilized printing technique, used to apply text and images across a diverse array of materials, including glass, cardboard, fabric, plastic, and wood. This method has evolved significantly over the centuries, driven by technological advancements and a broadening selection of substrates. One of screen printing's key advantages is its capability to deposit larger volumes of ink compared to flexography or offset printing. This characteristic facilitates the production of intricate designs that can be reproduced thousands of times without loss of detail. Consequently, screen printing has emerged as a preferred solution across various industries, particularly for label designs requiring higher ink loads and vibrant colors, and is often combined with other printing techniques for enhanced results.

In the context of Pressure-Sensitive Labels (PSL), screen printing holds particular significance, especially in narrow web applications. It excels in providing superior ink coverage, making it ideal for small text and white ink layers that require opacity. The combination of screen printing with flexography, stamping, and letterpress techniques enhances visual effects and textures, rendering it an exceptional choice for creating eye-catching labels that demand attention on the shelf.

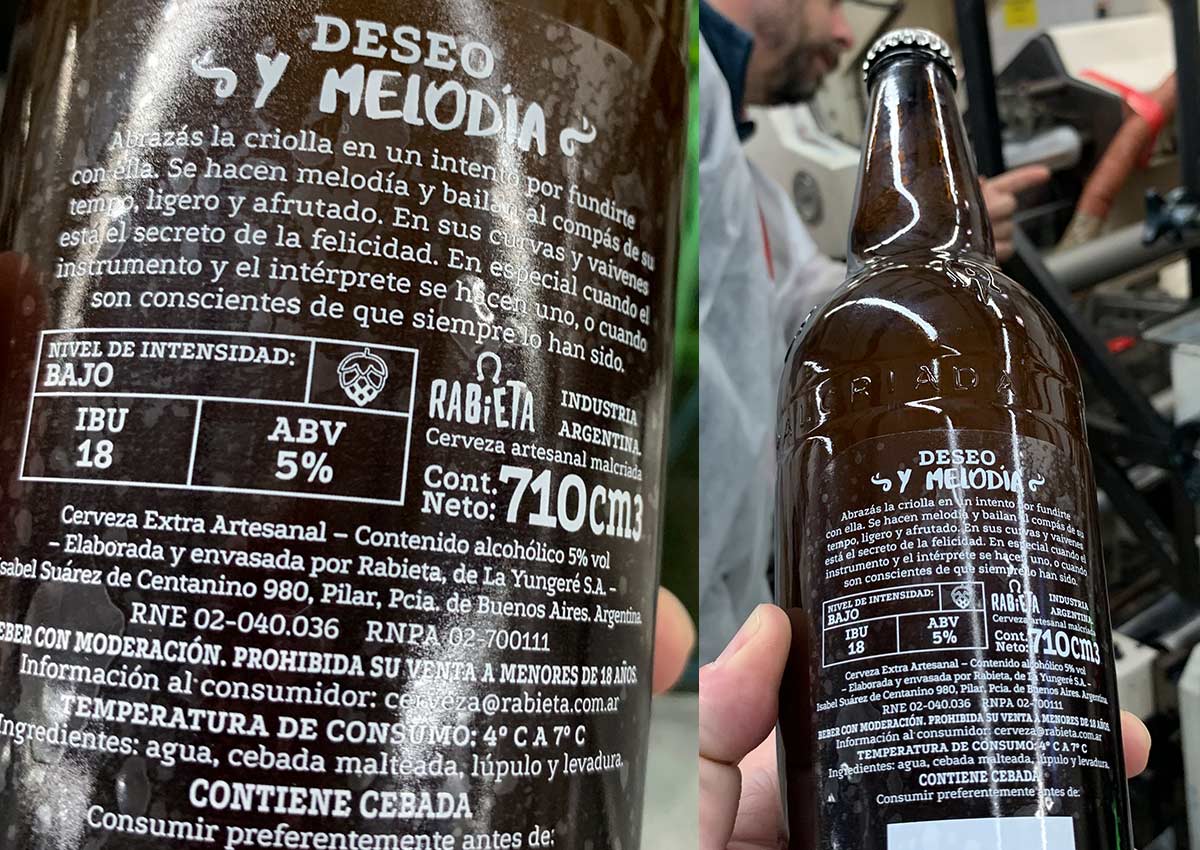

At Imaginity, we have effectively harnessed the power of screen printing in numerous packaging design projects for clients in the beer sector, including Rabieta and Cerveza Águila, as well as in the cosmetics and personal care industries.

The advantages of screen printing are numerous. It serves as a cost-effective solution, enabling large-scale production of complex designs without significantly inflating production costs. Moreover, the durability and resistance of screen-printed products make them suitable for a variety of applications, ensuring they withstand the rigors of daily use. With its ability to deliver exceptionally precise finishing, screen printing remains a trusted method for producing high-quality, striking products that leave a lasting impression in the marketplace.

The most commonly used term for "thermo-shrinkable materials" is "shrink film" or "shrink wrap." These materials shrink when heat is applied, making them ideal for packaging applications where a tight, secure fit is desired. Shrink film is often used for packaging products in various industries, including food, beverages, and consumer goods.

Flexo printing on shrink film presents an innovative approach to packaging design, offering brands the ability to create visually compelling and effective presentations for their products. The combination of flexographic printing with heat shrinkable materials, followed by application through a shrink oven, results in striking and dynamic packaging that enhances product appeal.

One of the primary advantages of using flexo printing on shrink sleeves is the capability to print across the entire surface of the packaging. This maximizes the available space for branding and product information, allowing for vibrant graphics and comprehensive messaging that effectively captures consumer attention. With the flexibility of flexography, brands can achieve high-quality prints with rich colors and intricate designs that align with their identity and marketing strategies.

However, successful implementation requires careful consideration of shrinkage areas during the design process. It's crucial to compensate for these areas in pre-press to ensure that the final printed design maintains its intended look after the shrinkage process. By accurately predicting and adjusting for shrinkage, brands can achieve optimal results, ensuring that their packaging not only looks good but also performs well on the shelf.

Shrink film is widely utilized in various packaging design applications, offering versatility and effectiveness for different products. Common applications include shrink wrap for multipacks, which securely bundles multiple items together, making them easier to handle and store. Shrink sleeves are often employed for smaller production runs in can filling (i.e. in the craft beer industry), providing an eye-catching label that conforms tightly to the can's shape. Additionally, full-body sleeves are frequently used in special packaging editions or packvertising campaigns, allowing brands to create stunning visual presentations that enhance shelf appeal and communicate their identity effectively. This adaptability makes shrink film an essential choice in modern packaging solutions.

At Imaginity, we have significant expertise in shrink film printing for packaging design across a variety of applications, including can labeling, shrink-film multipacks, and full-body sleeves for numerous brands. Our expertise in this area enables us to deliver innovative and visually compelling packaging solutions that not only enhance product presentation but also effectively communicate brand identity. We understand the details of working with shrinkable materials and are committed to helping our clients achieve exceptional results that stand out in today's competitive market.

The direct printing over aluminum cans is commonly referred to as direct-to-container printing or direct printing on cans. This method allows for printing directly onto the surface of the can without the need for labels, providing a seamless and high-quality finish.

Direct printing on beverage or aerosol cans is typically done using a method called dry offset printing. This technique is a form of lithography that allows for high-quality images and designs to be printed directly onto the surface of cans. Dry offset printing is preferred for its ability to produce vibrant colors and sharp details while being efficient for large production runs.

In dry offset printing, colors are applied in separate layers, and one of the limitations of this technique is that colors typically cannot superimpose effectively. This means that if multiple colors are printed on top of one another, they may not blend seamlessly or create the desired visual effects. Instead, each color is printed individually, and any overlap can lead to issues like misregistration or muddying of the colors.

The ability to print directly on the cans not only increases the visual impact of the product but also offers a more sustainable solution by reducing the need for additional labeling materials. However, this printing method generally requires careful consideration of design elements, such as ensuring, in most applications, that colors do not overlap.

At Imaginity, we have a proven track record in can printing for a variety of products, including soft drinks, beer, functional beverages, and personal care items. By adhering to best practices and design guidelines, we help brands achieve high-quality results that not only stand out in a competitive market but also ensure their products are easily identifiable to consumers. Our expertise in direct printing techniques enables us to create vibrant, impactful designs that enhance brand visibility and appeal on store shelves.

Offset printing is among the most favored methods for brands seeking to produce packaging due to its ability to deliver consistent quality across large volumes. The flexibility of this printing technique allows for a wide range of substrate options, from standard paper to specialized materials, making it highly adaptable for various packaging needs.

The offset printing method is a widely recognized indirect printing technique, primarily used for high-quality packaging applications. Unlike direct printing systems, the substrate—usually paper—never comes into direct contact with the printing plate. Instead, the process involves a series of transfers where ink moves from an aluminum plate to a rubber blanket cylinder before finally being applied to the paper or other substrate. This multi-step transfer process minimizes wear on the printing plates and ensures a clean, precise image transfer, as pressure is exerted between the blanket cylinder and the impression cylinder, resulting in sharp and vivid prints.

In offset printing, monochromatic plates are utilized, which means a separate plate must be created for each color to be printed. For full-color images, this typically requires four distinct plates, one for each of the colors in the CMYK color model: cyan, magenta, yellow, and black. This process, known as four-color printing, enables brands to achieve vibrant, photorealistic images on their packaging, effectively capturing the attention of consumers while conveying essential product information and brand identity.

In addition to the CMYK color model, offset printing can also accommodate spot colors, such as those specified in the Pantone Matching System (PMS). Spot colors are pre-mixed inks that provide consistent and precise color reproduction, making them ideal for branding elements that require exact color matching. When using spot colors, a separate plate is created for each specific color, allowing brands to achieve vibrant hues that may not be attainable through the standard CMYK process. This is particularly beneficial for logos and key visual elements where brand consistency is crucial. By incorporating spot or Pantone colors into their packaging designs, brands can enhance their visual impact and ensure their products stand out on the shelves.

At Imaginity, we have extensive experience in packaging design utilizing offset printing in conjunction with various finishing techniques, such as gloss or matte coatings and dry embossing. These enhancements significantly elevate the visual appeal of packaging across diverse industries, ensuring that our clients’ products stand out in a competitive marketplace.

Digital offset printing represents a significant evolution in printing technology, blending the benefits of traditional offset printing with the advantages of digital processes. Unlike conventional offset printing, where ink is transferred from plates to a substrate, digital offset utilizes digital files to produce prints directly, eliminating the need for physical plates. This approach allows for quicker setup times, reduced costs for short runs, and greater flexibility in design changes.

Digital offset printing is particularly advantageous for producing short runs, allowing brands to create smaller quantities of high-quality printed materials without the traditional setup costs associated with conventional printing methods.

Furthermore, digital offset printing offers enhanced customization options. Brands can easily create variable data prints, allowing for personalized packaging solutions tailored to specific markets or consumer segments. This capability is invaluable for promotional campaigns, limited editions, or seasonal products, where unique designs can help differentiate a brand in a competitive landscape.

At Imaginity, we harness the potential of digital offset printing to create stunning designs that resonate with consumers while ensuring efficient production processes. By leveraging this modern printing technology, we help our clients achieve their branding goals and deliver exceptional products that stand out on the shelves.

Rotogravure, or gravure printing, is a high-quality, intaglio printing process widely used in the packaging industry for its ability to produce intricate designs and vibrant colors. This method involves engraving an image onto a rotating cylinder, where the recessed areas hold the ink. As the cylinder rotates, it transfers the ink to the substrate, which can include various materials such as paper, plastic films, and aluminum foil.

One of the key advantages of rotogravure is its capability for high-speed production, making it ideal for large-volume runs. This efficiency allows brands to meet high demand while maintaining consistent quality across extensive print runs.

The process excels in producing fine details and rich gradients, making it suitable for complex designs that require a high level of detail. Additionally, rotogravure printing supports a wide range of ink types, including water-based, solvent-based, and UV inks, enhancing its versatility in various packaging applications.

Despite the higher initial costs associated with cylinder preparation, the long print runs and superior quality often justify the investment for brands aiming to make a strong visual impact in large-volume applications.

The finishing process in packaging design printing plays a crucial role in enhancing the visual appeal and functionality of printed materials. This stage encompasses a variety of techniques applied after the initial printing to add texture, durability, and design elements that elevate the overall quality of the product.

One common finishing technique is coating, which can be either gloss or matte. Gloss coatings provide a shiny finish that enhances color vibrancy and makes images pop, while matte coatings offer a sophisticated, non-reflective surface that can convey elegance and refinement. Coatings also serve to protect the printed surface from wear, moisture, and fading, extending the lifespan of the product.

Embossing and debossing are other popular finishing methods that create a tactile experience by raising or lowering specific areas of the printed material. This adds depth and dimension, making designs more engaging and appealing to touch. Foil stamping is another technique that applies metallic foil to specific areas, creating striking visual contrasts and a sense of luxury that can attract consumer attention.

Die-cutting is also integral to the finishing process, allowing for unique shapes and custom designs that stand out in a crowded market. This technique is commonly used for packaging, labels, and promotional materials, enabling brands to create distinctive silhouettes that enhance their identity.

Finally, packaging finishing may include features such as windows, handles, or special closures that not only improve usability but also contribute to a memorable unboxing experience for consumers. Overall, the finishing process is essential in printing, as it not only enhances aesthetic appeal but also adds value and functionality to the final product, helping brands make a lasting impression on their audience.

Corrugated cardboard printing is a specialized technique designed to produce high-quality graphics and images on corrugated packaging materials, which are widely used in the shipping and packaging industry. This material consists of a fluted inner layer sandwiched between two flat liners, providing strength and durability while remaining lightweight.

Flexographic printing is commonly employed for large-scale runs due to its speed and efficiency, making it ideal for creating custom boxes, display cartons, and shipping containers.

Additionally, corrugated cardboard is an environmentally friendly option, as it is recyclable and often made from recycled materials. This aspect aligns with the growing consumer demand for sustainable packaging solutions, making printed corrugated cardboard an attractive choice for brands committed to eco-friendly practices.

The printing process on corrugated cardboard typically involves flexography, but with fewer printing details and a more limited color palette than what is used in narrow-web pressure-sensitive label (PSL) flexo printing. In corrugated printing, GCMI color standards are usually employed instead of the Pantone system. The GCMI standard is a 60-color guide developed in the 1950s by the Glass Container Manufacturers Institute, now known as the Glass Packaging Institute. Digital printing is beginning to gain popularity for short runs and personalized packaging, offering flexibility in design changes and quicker turnaround times.

At Imaginity, we bring years of expertise in corrugated cardboard printing, helping brands achieve stunning packaging designs that not only protect their products but also enhance their market presence.