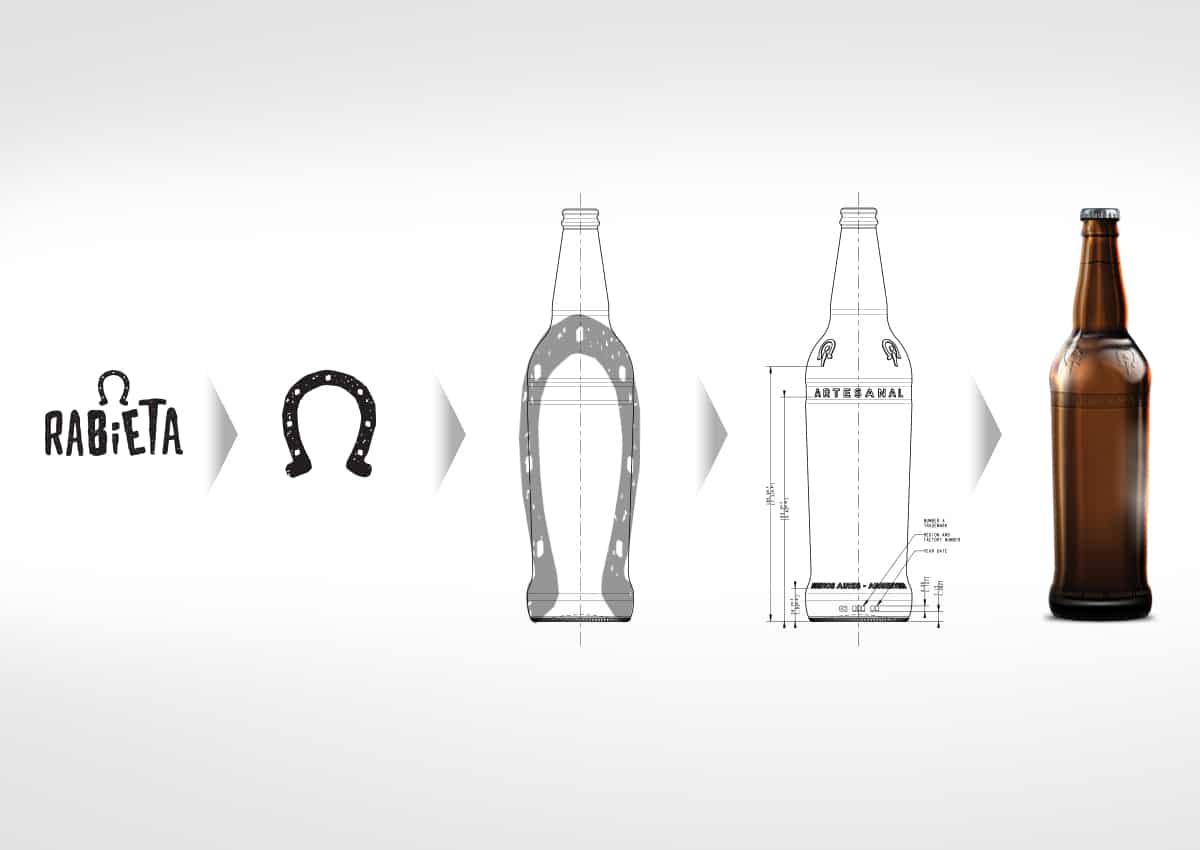

Rabieta Craft Beer Bottle Design

Case study

![]()

Rabieta, a craft beer rooted in Argentina’s equestrian passion and the polo farms of Pilar, Buenos Aires, needed a distinctive bottle that echoed its artisanal origins. Our goal was to create a bottle with both a rustic, crafted look and a functional design suited for brewery processes and glass manufacturing specifications.

Concept Development & Research

-

Brand Story and Inspiration: The bottle’s design was inspired by Rabieta’s connection to polo culture. We drew on the shape of a horseshoe for the bottle’s shoulders, symbolizing strength, resilience, and the rural equestrian heritage.

-

Artisanal Look and Feel: To reinforce its handcrafted image, we aimed for a shape and texture that would stand out among craft beers, balancing rustic and refined qualities that align with the brand’s identity.

Initial Sketches & Ideation

-

Shape Exploration: Our team created preliminary sketches to explore variations on shoulder shape, neck length, and volume. Experimentation with embossed elements allowed us to highlight branding elements, like logos or subtle design details, for added visual depth.

-

Functional Zone Design: From the beginning, we factored in specific requirements for an indented labeling area. This protected zone was strategically placed to avoid wear from transport and to ensure proper alignment and durability on the brewery’s filling line.

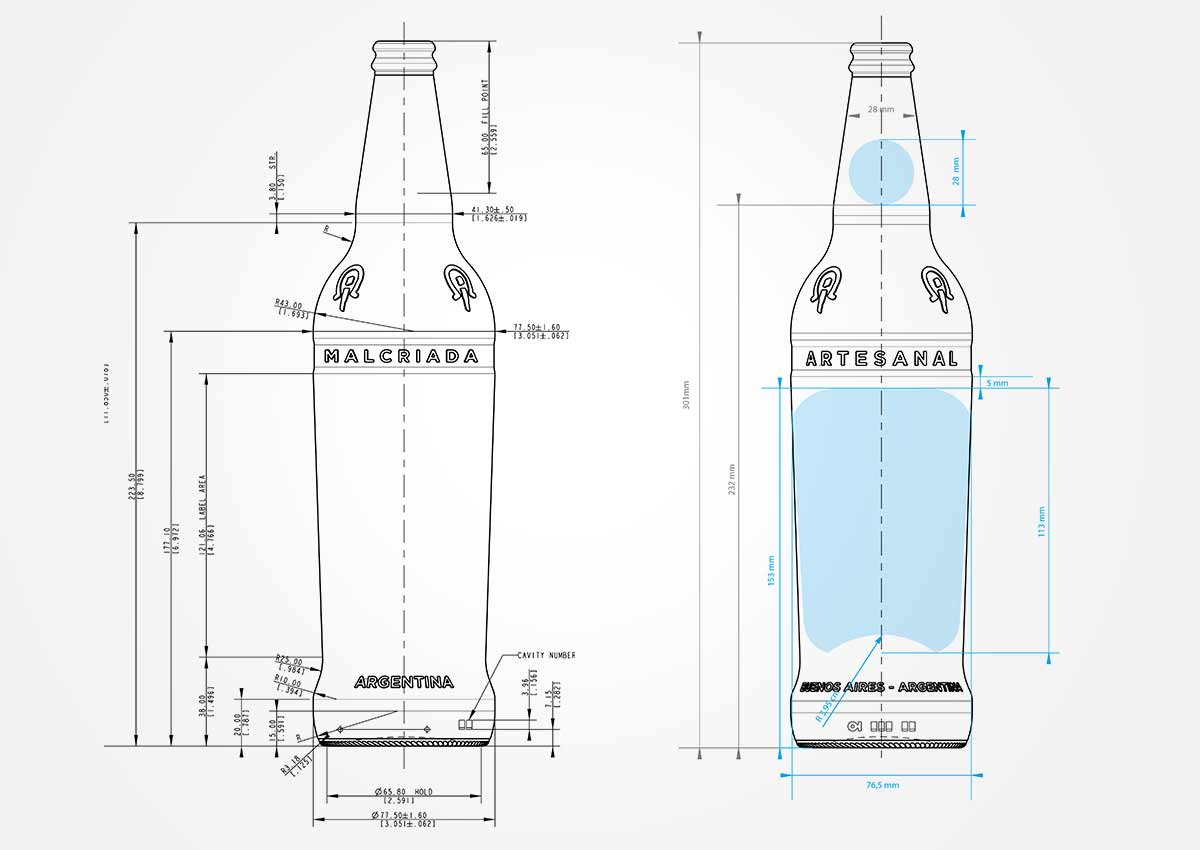

2D Modeling & Preliminary Sizing

-

Proportional Balance and Ergonomics: In the initial 2D modeling phase, we carefully balanced the bottle’s aesthetics with ergonomic considerations to ensure a comfortable grip, stable weight distribution, and ease of pouring. Every line and curve was designed to enhance usability and maintain balance in both visual and functional aspects.

-

Technical Constraints: We took into account technical restrictions, such as requirements for transport on the filling line and specific limitations on the bottle’s base shape as specified by the glass manufacturer. These considerations guided the structural design and ensured compatibility with the production process.

-

Cap and Closure Compatibility: The neck and finish were designed to align with the brewery’s equipment, meeting specific neck shape requirements for a crown cap and balancing both aesthetic and functional considerations.

-

Engraving Details: To reinforce the brand’s identity, we incorporated engraved details, including a horseshoe motif and the brand slogan, "Pampered Craft Beer," along with its origin in Buenos Aires, Argentina. These elements were seamlessly integrated to convey authenticity and a sense of place, adding to the bottle’s artisanal character.

As a result of the 2D design, we produced detailed preliminary blueprints of the bottle, specifying preliminary dimensions and estimated volume capacity. These blueprints were meticulously aligned with the requirements outlined in the client’s design brief, ensuring that the bottle would meet the desired volume capacity while maintaining the proportions and functional attributes we envisioned. These initial blueprints served as a foundation for the next design stages, providing a clear visual reference and technical guidelines for transitioning to 3D modeling and subsequent prototyping.

Label Design & Application

-

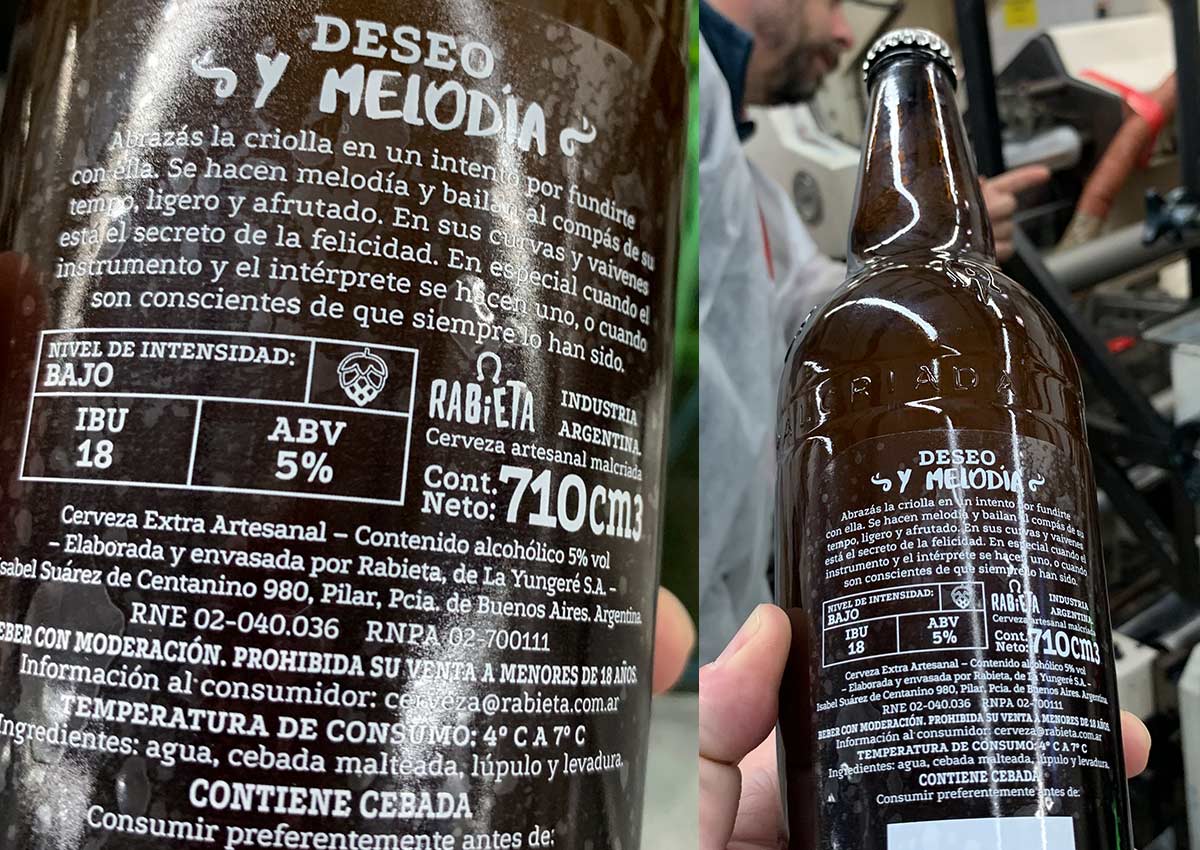

Integrated Labeling Design: In parallel with bottle development, we designed a coordinated label set, including a front label, neck label, and back label, to enhance brand visibility. Each label’s placement and shape were optimized for the indented protected labeling area.

-

Crafted Visual Appeal: The labels were crafted to convey Rabieta’s artisanal spirit and included pressure-sensitive label (PSL) technology to provide a no-label look on the back panel, with white printing that reinforces the bottle’s handcrafted aesthetic.

This process ensured that Rabieta’s proprietary glass bottle not only embodied the brand’s equestrian heritage but also met practical brewery needs and glass manufacturing standards, resulting in a distinct, durable, and visually impactful final product.

3D Modeling & Rendering

-

Detailed CAD Modeling: We translated the design into precise 3D CAD models, carefully refining the bottle’s shape and neck finish to meet the target volume of 710 ml. These models addressed technical aspects to minimize potential production issues, ensuring a streamlined manufacturing process.

-

Rendering for Visualization: High-quality, photorealistic renderings allowed stakeholders to preview the final design in detail, supporting informed feedback and adjustments to perfect the look and functionality of the bottle.

-

Rapid Prototyping & Refinement: Initial 3D-printed prototypes allowed us to evaluate physical interaction, focusing on “prehensile” aspects—how users hold, pour, and handle the bottle. This hands-on testing guided refinements to improve functionality and user experience.

-

Collaboration with Manufacturer and Brewery Team: We worked closely with both the glass manufacturer and the brewery’s technical team to confirm that the bottle design complied with production and filling requirements. This collaboration helped preempt any potential conflicts related to manufacturing constraints or filling line specifications, ensuring a smooth transition from design to production.

Design Finalization

-

Final modeling: To ensure durability, we calculated final volume specifications, and other requirements set forth in the interaction with the glass manufacturer and brewery team.

-

Production Optimization: We collaborated closely with the glass manufacturer to finalize the mold design and prepare for efficient production while adhering to technical restrictions.

-

Trial Production Molds: The initial molds were produced on a small scale, enabling us to assess the bottle’s integrity and design elements in real glass before mass production. Once the trial molds met specifications, they were replicated for full production.

-

Sample Runs and Quality Assurance: Sample bottles produced with trial molds were rigorously tested for stability, durability, and alignment on the filling line. Quality checks ensured that the bottle was fully ready for larger-scale manufacturing.

-

Approval of Trial Molds and Production Mold Finalization With the trial molds approved—having met all design and functional specifications without the need for adjustments—the molds were replicated to create the full set of cavities required for production.