Bottle Design Process: Packaging Design From Concept to Production

![]()

At Imaginity, we specialize in packaging design that blends brand storytelling, functionality, and production efficiency. Whether developing a glass or plastic bottle, our design process ensures your packaging not only looks stunning but also enhances usability, sustainability, and shelf impact. From initial concept to final production, we create custom bottle designs that reinforce brand identity and drive consumer engagement.

Here’s how our bottle packaging design process ensures success:.

Market & User Research:

We study consumer behavior to ensure the design meets expectations for ergonomics, sustainability, and usability. Additionally, we help brands define sustainability goals, such as recyclability and lightweighting, to align with eco-conscious market demands.

A bottle’s functionality and aesthetics are critical to its success. The volume and size must be carefully chosen based on the product category, whether it’s beverages, cosmetics, cleaning products, or pharmaceuticals. The material must be compatible with the product it contains, ensuring safety and durability. The choice of closure—whether a screw cap, cork, pump, or sprayer—affects both functionality and consumer experience. Lastly, the visual identity of the bottle should reflect the brand’s positioning, whether conveying premium elegance, a bold and modern image, or a sustainable and minimalist appeal.

At Imaginity, as a specialized packaging design agency, we ensure that every aspect of the bottle, from its structure to its branding and materials, aligns seamlessly with the brand’s strategy.

2. Material Selection

At Imaginity, we balance aesthetic appeal and structural integrity to create bottles that are both functional and visually compelling.

Glass Bottle Design

For glass bottles, we consider factors such as clarity, color, and weight. Clear, amber, or green glass can enhance branding while providing UV protection where needed. Embossing and debossing details add texture and elevate the perception of quality. A heavier glass bottle conveys a premium feel, while lightweight options improve cost efficiency and logistics.

Plastic Bottle Design

For plastic bottles, selecting the right material is essential. HDPE (High-Density Polyethylene) is durable, impact-resistant, and widely recyclable, making it ideal for personal care and household products. PET (Polyethylene terephthalate) is transparent, lightweight, and commonly used for beverages, while PP (Polypropylene) is heat-resistant and suitable for pumps and closures. Sustainability is a key focus in our design process. We explore solutions like post-consumer recycled materials (rPEAD, rPET), biodegradable plastics, and refillable bottle systems. Our approach also includes optimizing wall thickness to reduce material waste without compromising durability.

By working with Imaginity, brands gain access to cutting-edge packaging design solutions that meet both aesthetic and functional needs.

3. Conceptual Design, Sketching & 2D Design

At Imaginity, we believe that strong bottle packaging design starts with a solid conceptual foundation. Before moving into 3D modeling, we focus on exploring design concepts through sketching and 2D visualization. This phase allows us to quickly explore multiple creative directions and refine the best solutions before investing time in complex digital modeling.

The process begins with freehand sketching, where our designers create quick, expressive sketches to explore shape, form, and proportion. These early-stage sketches help define the bottle’s overall silhouette, its relationship with the label or branding elements, and ergonomic considerations. By working through multiple iterations, we evaluate how different design directions align with the brand’s identity, market positioning, and functional needs.

Once the best initial concepts are selected, we move to detailed 2D design, where sketches are refined into precise digital illustrations. Using tools like Adobe Illustrator, we create vector-based drawings that define the bottle’s exact dimensions, surface details, label positioning, and closure integration. This stage allows us to establish key design elements such as symmetry, contour refinements, and branding placements before committing to a 3D structure.

In addition to defining the form, 2D design includes exploring branding elements, such as typography, iconography, and graphical layouts. This step ensures that the bottle’s structure works harmoniously with its labeling, embossed details, or direct printing. We also consider production constraints, mold feasibility, and printing tolerances, ensuring that the design can transition smoothly into manufacturing.

By dedicating time to conceptual sketching and 2D design, we create a strong foundation for the next stage—3D modeling and prototyping—which allows for a seamless transition from design visualization to production feasibility.

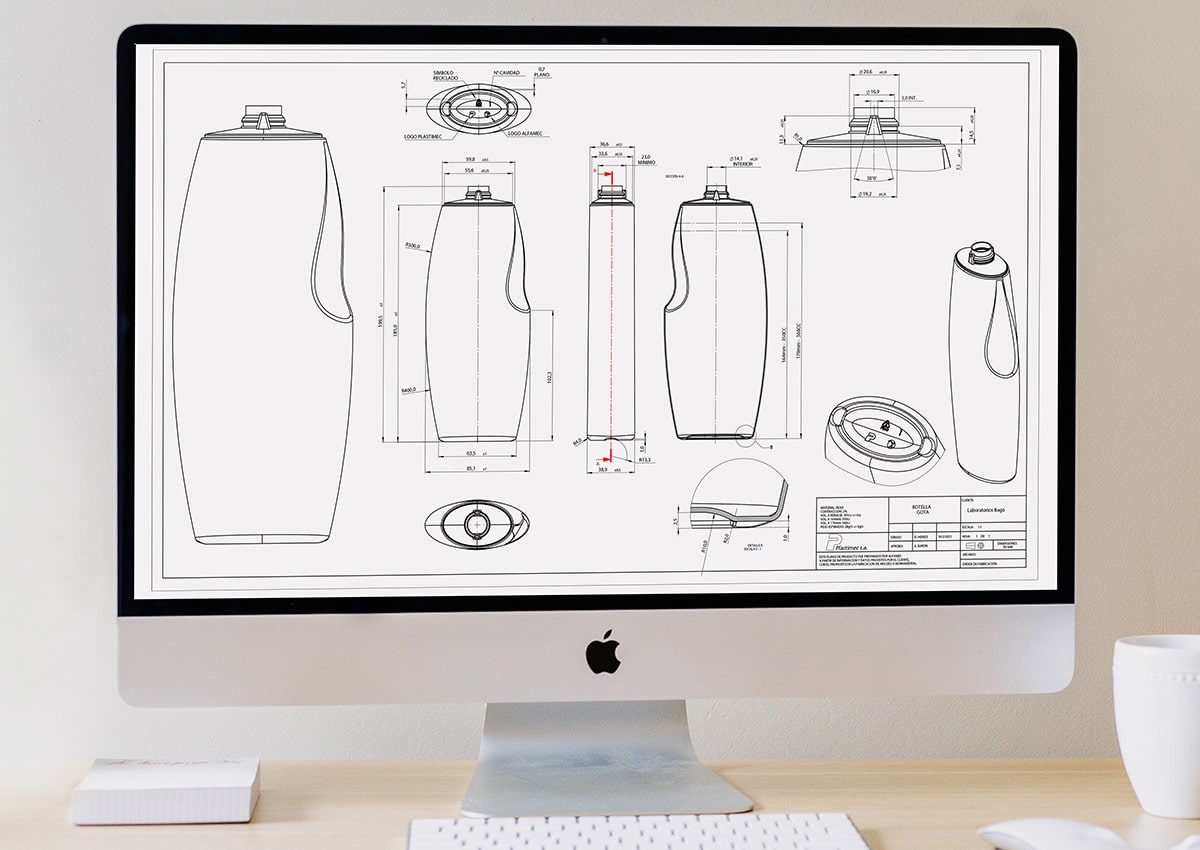

3D CAD Modeling & Digital Simulations:

• Rendered visuals to test shape, label placement, and shelf presence.

• Simulation of pressure resistance for transport and storage.

• Prototype Development:

• 3D-printed or CNC-machined prototypes to test ergonomics and grip.

• Blow molding trials for plastic bottles to ensure structural integrity.

• Glass mold prototypes to assess weight, clarity, and branding effects.

By working with an experienced design agency for packaging, brands can perfect their bottle’s usability, durability, and shelf impact before investing in large-scale production.

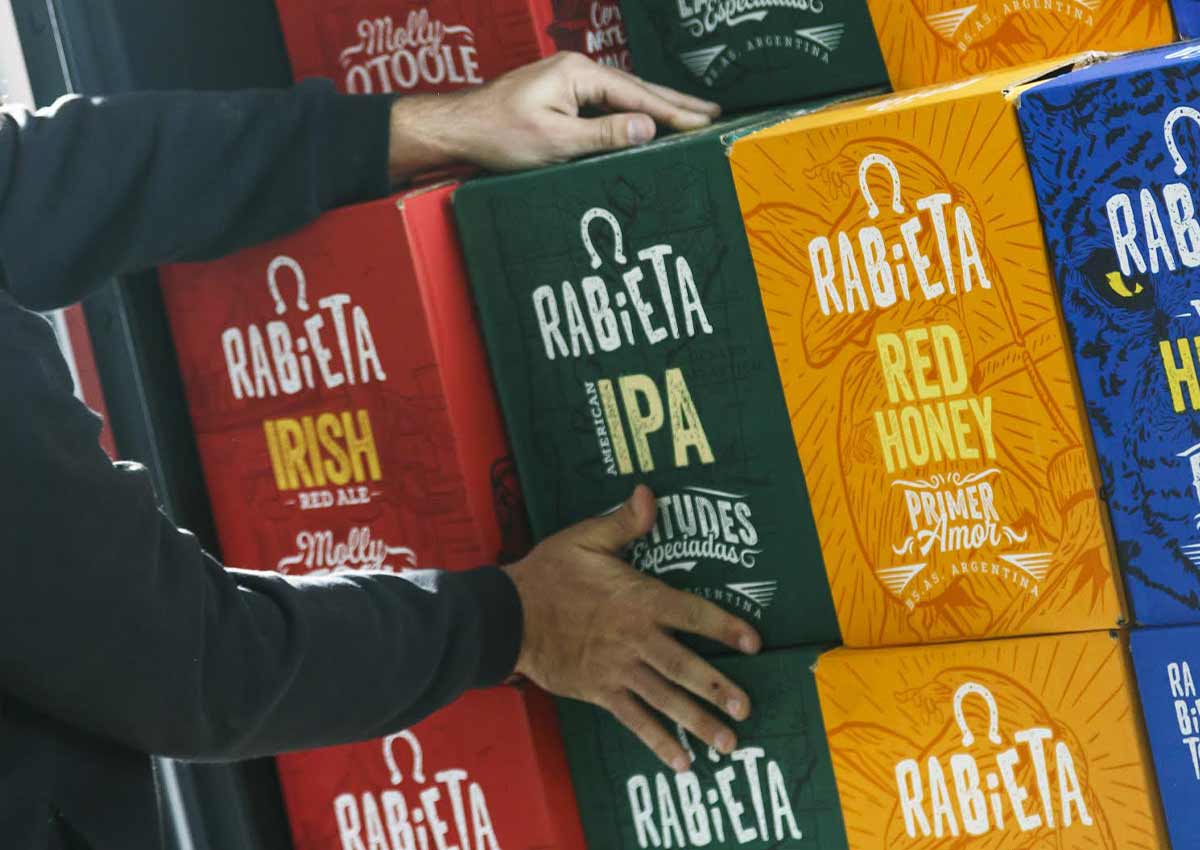

Labeling Methods:

• Pressure-sensitive labels for a seamless, no-label look.

• Shrink sleeves for full-body designs.

• Direct screen printing for high-end glass bottles.

• Embossing & Texture:

• Glass bottles: Raised logos, patterns, or texture for premium differentiation.

• Plastic bottles: Molded grip zones for ergonomic appeal.

• Color & Finishing Techniques:

• Matte or gloss coatings, metallic finishes, and specialty inks.

• Transparent windows or die-cuts to showcase the product inside.

By leveraging the expertise of a packaging design agency, brands can create packaging that not only looks stunning but also enhances brand recognition and consumer engagement.

Glass Manufacturing Process:

• Custom mold creation for unique shapes.

• Blow-and-blow or press-and-blow techniques to form the bottles.

• Annealing process to ensure durability and prevent stress fractures.

• Plastic Manufacturing Process:

• Blow molding (extrusion or injection) for PEAD, PET, and PP bottles.

• Injection molding for caps and closures.

• Material reduction techniques to optimize weight and cost.

• Quality Control Measures:

• Drop tests, pressure resistance checks, and leakage testing.

• Regulatory compliance with FDA, EU packaging regulations, and food-grade safety standards.

A design agency specializing in packaging can ensure seamless production coordination between suppliers and manufacturers, reducing errors and maximizing efficiency.

Packaging Efficiency & Cost Reduction:

• Stackable designs to maximize transport efficiency.

• Lightweight materials to reduce carbon footprint.

• Sustainability Innovations:

• Mono-material bottles for easier recycling.

• Refillable and reusable bottle systems for sustainable brands.

• Use of post-consumer recycled materials (PCR) to meet eco-conscious consumer demand.

Partnering with a design agency focused on sustainable packaging ensures that brands align with environmental regulations and consumer expectations.

Final Thoughts: Why Work with a Packaging Design Agency?

Creating a successful bottle packaging design requires expertise in branding, structural integrity, materials, and production processes. Whether designing for premium glass bottles or cost-effective plastic packaging, an experienced design agency can:

Develop a distinctive and functional bottle shape

➜ Ensure manufacturability and sustainability

➜ Enhance branding through labels, embossing, and textures

➜ Optimize logistics and cost-efficiency If you’re looking for packaging design experts to elevate your bottle design, consider working with a specialized packaging design agency that understands both aesthetic and technical requirements.

Would you like to explore custom bottle packaging solutions for your brand? Let’s discuss how we can create a design that stands out on the shelf and meets your business goals.